Contec is an environmentally conscious manufacturer of products from old tires, such as reclaimed carbon black and pyrolysis oil. By adhering to the circular economy policy, the company contributes to solving the global environmental problem of used tires. In the EU alone, more than 3 million tons of tires are recycled annually (ETRMA, 2018).

One of the reasons why Contec wanted us to calculate the carbon footprint of its flagship products was growing environmental awareness. The EU regulations currently in force focus more and more on reducing the emission of processes, and recyclers want to understand and reduce the carbon footprint of own products.

“As part of the circular economy model, Contec supports the transformation of the tire industry according to the concept of a circular economy. We do it by introducing sustainable products to the market with full transparency of the supply chain”, comments Klaudia Końska, R&D Specialist at Contec.

Each process of calculating the carbon footprint of a product is similar, based on the GHG Protocol Product Life Cycle Accounting and Reporting Standard, September 2011. World Resources Institute and World Business Council for Sustainable Development. However, with each carbon footprint calculation project, we gain new insights and conclusions about the industry it affects.

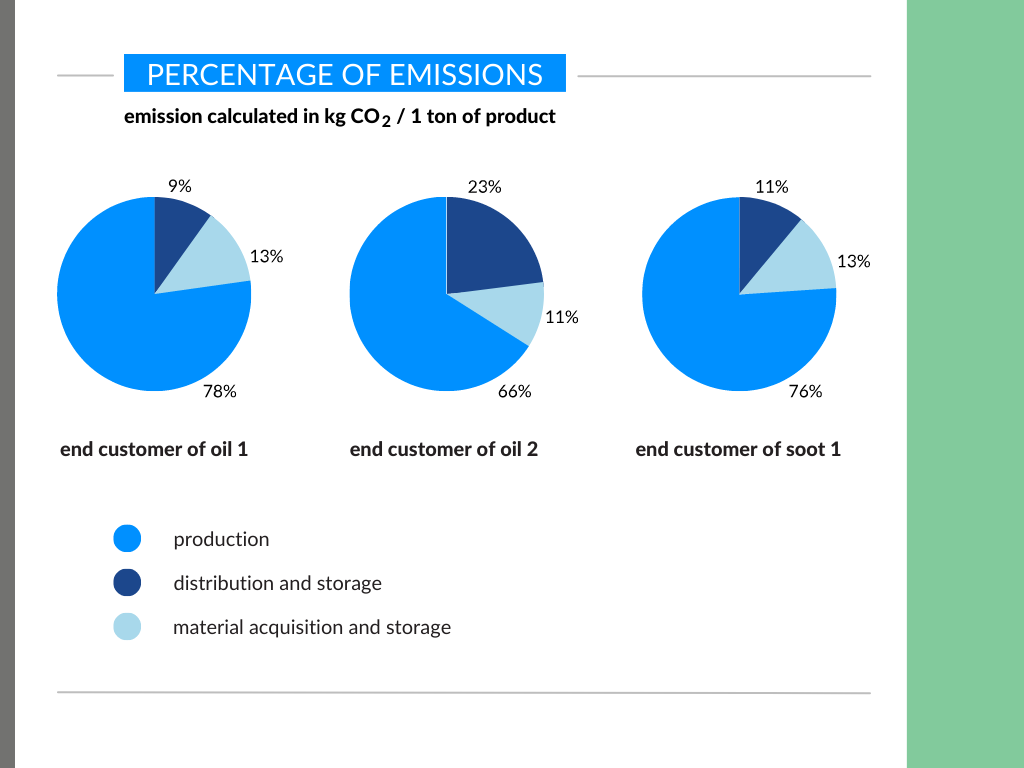

Apart from the aspect of delivery, the carbon footprint of pyrolysis oil is the same in both cases. The differences in the final result come from the distance and type of transport used in the delivery of the product. For customer no. 2, it is more than three times greater. Therefore, in the second case, the carbon footprint of the pyrolysis oil increased by 77.41 kg of CO2e per 1 ton of substance.

Calculating a product’s carbon footprint is never just an art for the sake of it. The Foundation always proposes mitigation measures in the production processes of our clients.

In summary of the project for Contec, we proposed the following options to reduce the carbon footprint of their products:

With the above as prerequisites in tender processes and by signaling to subcontractors the need to provide data as early as the contract signing stage, Contec contributes to building the awareness of suppliers and subcontractors.

“This interesting project required callaboration with a company that was able to provide precise operational data from their plant. On the other hand, we have faced challenge of noninformation from raw materials producers with regard to carbon footprint of their merchandise. Unfortunately, there are still few companies that calculate the carbon footprint of their products. Please note that with no data on emissions (carbon footprint) of a raw material or product, companies that use them in their production processes are unable to precisely determine their impact on the carbon footprint of own products and make conscious decisions regarding cooperation with suppliers who introduce reduction measures.”